19.04.21

When is my product subject to the ATEX Directive 2014/34/EU? How do I achieve conformity with this directive? Learn more about manufacturer obligations in connection with potentially explosive atmospheres.

The European ATEX Manufacturers Directive 2014/34/EU (sometimes referred to as "ATEX 114") regulates the placing on the market of products intended for use in potentially explosive atmospheres (so-called zones according to the ATEX Operators Directive 1999/92/EC ("ATEX 137") Annex I). In concrete terms, this means that manufacturers must comply with the requirements of this directive and subject their products to a conformity assessment procedure if the products are equipment and protective systems intended to be used in a potentially explosive atmosphere or components of such equipment and protective systems. In addition, safety, controlling and regulating devices which, although intended to be placed outside zones, are necessary for or contribute to the safe operation of equipment or protective systems inside zones, are also subject to the ATEX manufacturers' directive

If a manufacturer wants to use his product in potentially explosive atmospheres, he must first decide to which equipment group (Group I - underground mines and their surface installations or Group II - all others) and which equipment category (depending on the zone M1, M2, 1 G/D, 2 G/D or 3 G/D) the product is to be assigned. This defines the product's area of application. The product must then be checked for its own potential ignition sources. EN 1127-1 "Potentially explosive atmospheres - Explosion prevention and protection - Part 1: Basic concepts and methodology" is a helpful tool for making a hazard or ignition source analysis. Such ignition sources can include hot surfaces, sparks or electromagnetic waves.

In the next step, the appropriate measures are taken to avoid the existing ignition sources. So-called ignition protection types are used, such as flameproof enclosure. These are described in detail in separate standards, which in turn are harmonised with the ATEX manufacturers' directive. This means that compliance with the standards also means compliance with the requirements of the ATEX manufacturers' directive. A complete list of all standards harmonised to this directive can be found here. With group, category and the implemented type of protection, the conformity assessment procedure continues.

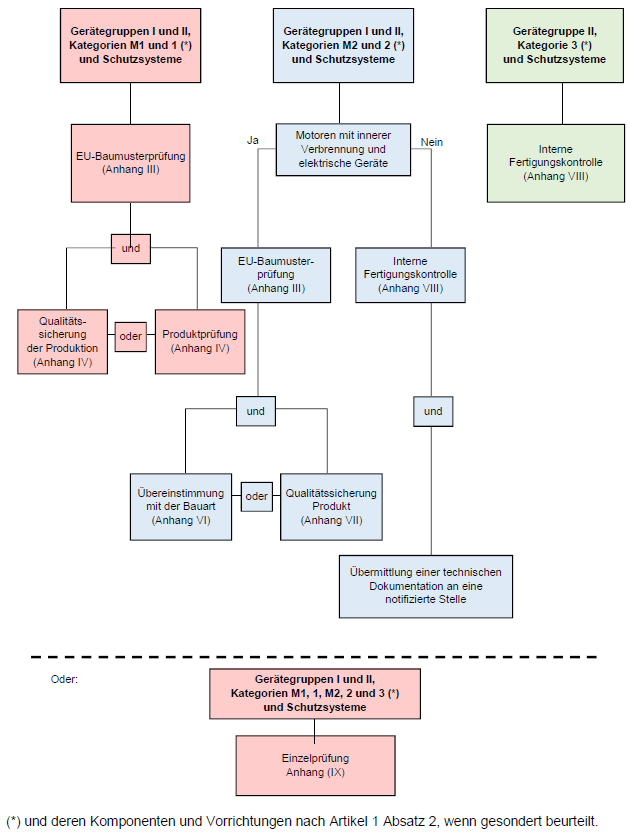

In order to build a product in conformity with the ATEX manufacturer's directive, a conformity assessment procedure must be carried out to check whether the requirements of the directive are met. Depending on the product's area of application, various procedures must be followed, which are described in detail in the directive's annexes and are summarised in the diagram below. In the case of a category 3 product, the manufacturer himself can prove conformity with an internal production control. For category 1, on the other hand, an EU type examination at a notified body (e.g. the TÜV) in combination with a quality assurance system or product control is required. This means that an independent body checks the technical documentation, the product itself and the quality assurance of the manufacturing process. A list of notified bodies in Europe can be found here. In principle, any notified body in Europe that is approved for the intended procedure is eligible.

Source: ATEX Guidelines for Directive 2014/34/EU, 3rd edition of May 2020.

If the product and the production process meet the necessary requirements, CE marking in accordance with the ATEX manufacturer's directive is carried out with the aid of the special explosion protection mark followed by information on the equipment group, category and further information such as the maximum surface temperature (or temperature class), the explosion group and the type of protection. Detailed information on the marking can be found, among other things, in the standard EN 60079-0 "Potentially explosive atmospheres - Part 0: Equipment - General requirements".

If you have any questions or need support, please do not hesitate to contact us. We will be happy to support you in the application of the ATEX manufacturer's directive!